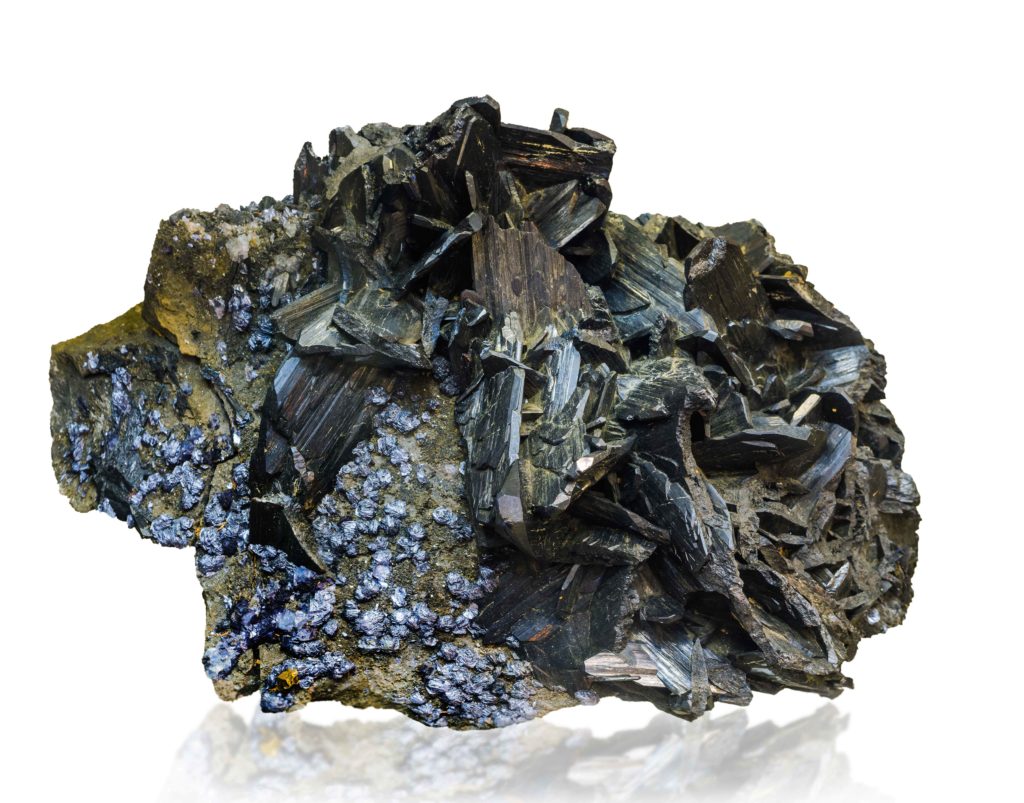

TUNGSTEN

Unmatched Strength. Precision That Performs.

At Recmet Group, we supply high-purity Tungsten metal and alloys engineered for maximum strength, density, and heat resistance — trusted across industries that demand performance beyond limits.

Product Overview

Tungsten (W), known for having the highest melting point among metals, is a critical material in high-performance industrial applications.

Recmet Group provides refined Tungsten and custom tungsten-based alloys that deliver superior hardness, wear resistance, and thermal stability.

Our Tungsten products meet global metallurgical standards and are manufactured with precision refining technologies, ensuring consistent quality and dimensional accuracy.

One of our ambitious future projects which we are spearheading at brisk pace is development of tungsten. Approximately half of the tungsten is consumed for the production of hard materials - namely tungsten carbide. Its other major use is in alloys and steels. Less than 10% is used in other chemical compounds.

Technical Specifications

| Parameter | Specification |

|---|---|

| Purity Level | 99.9% min |

| Density | 19.3 g/cm³ |

| Melting Point | 3422°C |

| Boiling Point | 5555°C |

| Tensile Strength | 500–1000 MPa (depending on form) |

| Forms Available | Rods, Wires, Pellets, Ingots, Powder |

| Standard | ASTM B760 / ISO 6848 / DIN EN 26848 |

Manufacturing Process

Precision-Crafted for Extreme Performance.

Our Tungsten production process is designed for uncompromising purity and consistency:

⚙️ Sourcing: Premium-grade tungsten ores and concentrates are sourced from trusted, environmentally responsible suppliers.

🔥 Reduction: Tungsten oxides are reduced in hydrogen furnaces to produce fine metallic powder.

🧪 Refining: Advanced purification removes trace impurities to achieve ultra-high purity metal.

🧱 Consolidation: Powder is sintered and pressed into bars, rods, or custom forms based on application needs.

✅ Quality Testing: Each lot undergoes spectrometric and mechanical testing to ensure uniformity and compliance with industry standards.

Applications

Recmet Tungsten is the preferred choice across industries that require extreme performance and precision:

🔩 Aerospace & Defense: Armor-piercing cores, counterweights, nozzles, and high-density components.

💡 Electronics: Filaments, contacts, and cathodes due to superior conductivity and heat resistance.

🔧 Industrial Tooling: Cutting tools, dies, and wear-resistant parts for high-pressure manufacturing.

🩻 Medical Equipment: Radiation shielding and imaging components.

⚙️ Energy Sector: Used in turbines, nuclear, and high-temperature furnace components.