SILVER

Refined Brilliance. Sustainable Strength.

At Recmet Group, we extract and refine high-purity Silver through advanced recovery processes — delivering quality that powers industries, innovation, and a cleaner tomorrow.

Product Overview

One of our most path-breaking projects is the extraction and recovery of precious metals — primarily Silver — at our state-of-the-art recycling and refining facility.

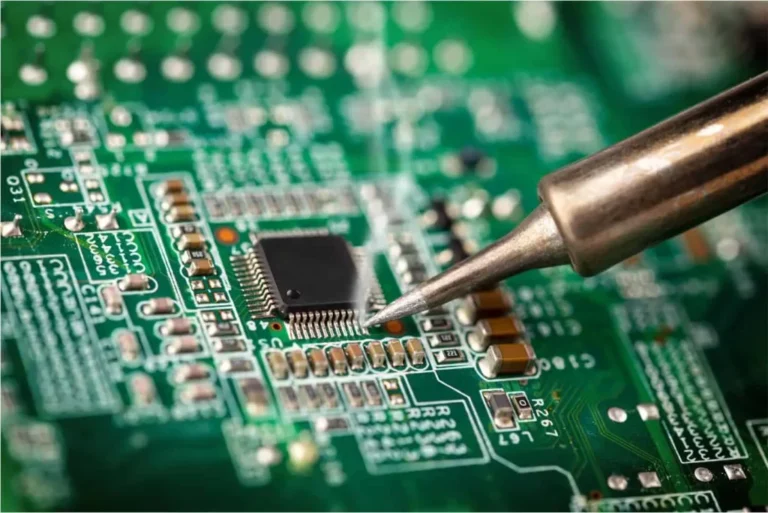

Using cutting-edge metallurgical techniques and eco-conscious recovery systems, Recmet Group extracts Silver from industrial residues, electronic waste, and battery scrap with exceptional purity and yield.

Silver is intrinsic to industrial demand — essential for electronics, LED chips, soldering materials, alloys, medical components, and glass coatings.

In fact, more than half of all global silver consumption is driven by industrial use, making it one of the most critical metals in modern manufacturing.

One of our path breaking projects is extraction of precious metals mainly silver at our plant. Silver is intrinsic to industrial demand in sector such as electronic, LED chips, solder, alloys, medicine, glass coating. In fact more than half of all silver consumption is for industrial purpose.

Technical Specifications

| Parameter | Specification |

|---|---|

| Purity | 99.90% – 99.99% |

| Density | 10.49 g/cm³ |

| Melting Point | 961.8°C |

| Electrical Conductivity | 63 × 10⁶ S/m |

| Thermal Conductivity | 429 W/m·K |

| Available Forms | Ingots, Granules, Sheets, Wire, Powder |

| Standard | ASTM B413 / IS 2112 / ISO 9202 |

Manufacturing Process

Refined with Precision. Engineered for Excellence.

Our Silver refining process ensures superior metal quality through carefully controlled stages of extraction and purification:

♻️ Raw Material Sourcing: Collection of silver-bearing scrap, electronic residues, and secondary waste.

🔥 Smelting & Separation: Initial melting and chemical separation remove impurities and isolate silver content.

⚗️ Electro-Refining: Advanced electrolysis ensures maximum purity with minimal energy waste.

🧱 Forming & Casting: Silver is molded into ingots, granules, or custom forms as per client specifications.

✅ Quality Control: Each batch undergoes spectrometric and conductivity testing to verify purity and performance.

Applications

Owing to its superior conductivity, reflectivity, and corrosion resistance, Recmet Silver is widely used across industries such as:

⚡ Electronics & Electricals: Conductors, switches, contacts, and soldering materials.

💡 LED & Semiconductor Industry: For chip bonding and high-precision circuits.

☀️ Renewable Energy: Photovoltaic cells and solar panels.

🏭 Industrial Manufacturing: Brazing alloys, catalysts, and coating materials.

🧪 Medical & Healthcare: Antibacterial applications and medical device coatings.

💍 Jewelry & Bullion: Premium-grade Silver for ornaments and investment.